Earlier today we posted about an article by Andrew Gilligan, the Telegraph‘s London Editor, in which he referred to the Cutty Sark restoration as “a clucking, Grade A, Bernard Matthews-class turkey.”

Earlier today we posted about an article by Andrew Gilligan, the Telegraph‘s London Editor, in which he referred to the Cutty Sark restoration as “a clucking, Grade A, Bernard Matthews-class turkey.”

For a more positive perspective on the restoration one could turn to the article by the Guardian’s Steve Rose, The Cutty Sark: hoist the main sail! which was mostly sunshine and roses, at least as compared to Mr. Gilligan’s comments.

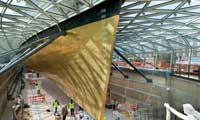

As a naval architect, I look at the keel of the Cutty Sark, wholly unsupported for its entire length, and I cringe. They still could have raised the ship up on a structural beam along the length of the keel, supported by widely spaced pillars. It would have not overly disrupted their corporate party space, whose creation seems to have overtaken the concerns about the structural integrity of the ship.

One point did make me less confident about the reporting done by Mr. Rose. He repeatedly commented on the Cutty Sark‘s “copper” bottom. The photograph in the Guardian clearly shows a yellow metal sheathing. Yellow copper? When did copper become yellow?

The metal is not copper. The sheathing on both the original Cutty Sark and the current renovation is Muntz metal, a brass alloy made of 60% copper, 40% zinc and a trace of iron. It was named for George Fredrick Muntz, a metal-roller of Birmingham, England who commercialized the alloy in 1832. Muntz metal was used as a replacement for copper sheathing on the bottom of ships. It had the same anti-fouling properties as copper at around two thirds of the price. Muntz metal was also stronger and more durable than copper.

So when Steve Rose writes: “The copper lining of the Cutty Sark’s hull, for example, was a military secret that gave Britain the edge: such boats resisted barnacles, making them faster than their rivals. To maintain the secret, though, only British copper could be used, driving the domestic mining industry,” he is getting both the history and the metal wrong.

Let us all just hope that the engineers who designed the new structure for the Cutty Sark, before hoisting her skyward, manage to get their design right. Only time will tell.

That picture sez it all. I read that article yesterday but couldn’t quite get exactly what they did; but that picture just boggles my mind. What happens when they get a severe wind storm?? Even bare rigging has an amazing amount of wind resistance, and I cannot imagine that the ship doesn’t move significantly side to side as the wind loads on the rigging come and go. In fact, the ship is designed to roll and it seems to me to be quite a challenge to overcome that tenancy and the forces involved.

Scary stuff….